Depackaging machines to separate organic content from its packaging in processing organic food waste.

The complete turnkey line of Smicon food waste processing equipment can bulk feed, presort, depack and purify food waste slurry and press the remaining packaging for a minimum loss of organics in the waste stream. Food waste collection trucks can back up and dump directly into the inground mixing feed bunkers holding up to 50 cubic yards of post-industrial, supermarket, or restaurant waste, or any kind of source separated organics.

Types of food waste accepted by Smicon:

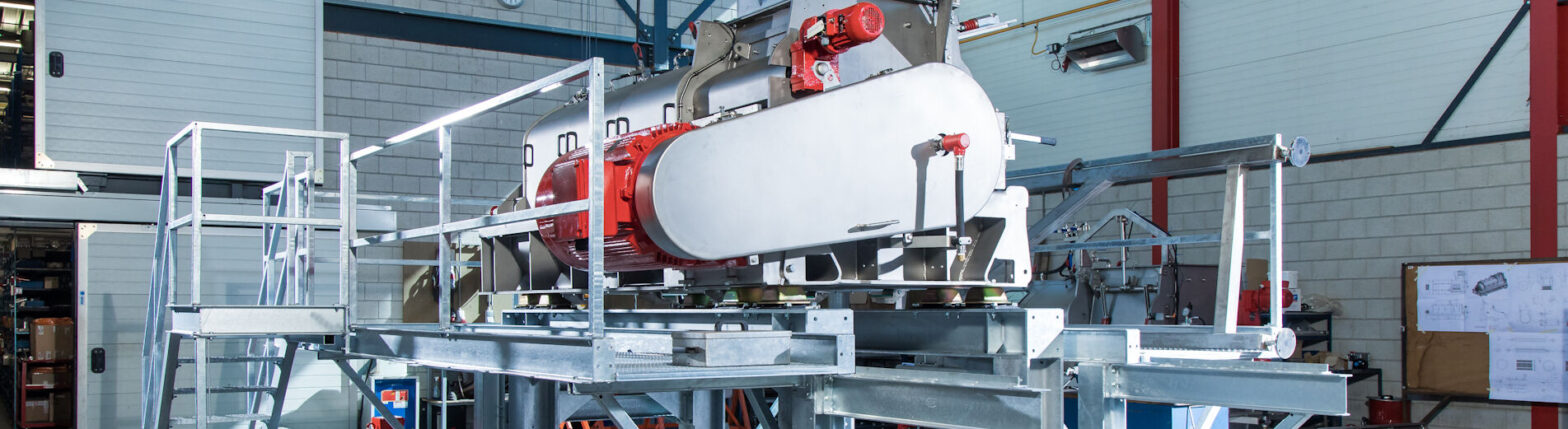

Specialized robust depackaging machines accept materials ranging from frozen foods, canned foods, vacuum packed meats and fish to bulk packaged breads, chips, snacks to chewy candy bars and bakery products. The gentle depacking process aims to keep packaging intact to produce clean food waste with a limited amount of contamination.

Long rotating screens with full circumference screening holes and various screen sizes allow for a variety of output streams without the need to add water. Packaged foods enter the machine, and two streams come out – clean, organic matter free of any packaging scraps; and empty, recyclable packaging free of organic matter.

Smicon’s experience in a variety of industries, combined with excellent workmanship in full stainless steel assures a long reliable lifecycle to process the most challenging feedstocks.

Cart tipping and wash line for concierge collection

Smicon has developed a phased starter package that allows you to start with base components and can grow with your business to a complete food processing powerhouse as your business expands. For concierge style food collection services, we can supply automated collection carts tippers, cart washlines and return system into outbound vans and flatbeds.

Food Waste Processing Use Case Examples:

Solid Food Waste

From plastic-wrapped bread…

To clean and uncontaminated organic flow…

Liquid Food Waste

From packages of plastic-bottled drinks…

To empty plastic bottles with no organic content…

SMIMO 120 and SMIMO 160 Features

- Robust and large inlet section

- Larger screen surface in the drum sections (see photo above) to maximize throughput capacity.

- Screens can be customized per section with different sizes depending on product, capacity, and separation quality demands.

- Option to clean the drum from the outside (spray nozzles). Shaft can be turned manually during maintenance and inspections.

Advantages over Other Brands

- Higher capacity

- More customizable screening options per section.

- No water required for separation

- Easier cleaning and maintenance.

- Robust construction prevents unnecessary failures

Food Waste Applications

- Pre-consumer, packaged food waste in all forms (except glass containers)

- Post-consumer, mixed source separated organics (SSO) from restaurants, grocery stores, sports venues, schools, etc.