Lubo’s stationary, mobile construction and demolition processing systems have perfected the technique of material separation through the use of various automated processes. Lubo’s core products are screens (for many materials), complete C&D systems, mobile screening machines, and semi-mobile installations. Lubo StarScreens®, such as the angled sorter, ONP, and OCC separators have been integrated into Bollegraaf single stream systems and material recovery facilities around the world. The heart of Lubo’s success is in its patented stars, which are available in various sizes and materials. Lubo stars have been proven to increase process efficiency for customers throughout the industry.

Lubo USA, LLC, a sister company of VAN DYK Recycling Solutions, was founded in 1996. VAN DYK is the sole distributor for Lubo Screening and Recycling Systems.

The Non-Wrapping ONP Screen

A high-capacity ONP screen that resists wrapping for an entire shift. Specially designed stars do not become loaded with film or other stringy material and do not let the separation capabilities of the screen become compromised. Peak performance for an entire shift and takes mere minutes to clean.

We have installed dozens of these screens for our customers and they are proven to work and increase productivity (see more here).

Elliptical Screen

A ballistic separator for accurate separation of 2D and 3D materials, a replacement for commingled or polishing screen. Striding paddles walk 2-dimensional objects over the screen (items like film bags and light sheet paper). Rigid items (bottles, cans, 3-D cardboard) bounce back. Paddles have true 2-inch holes in them to allow the last bit of glass fines to fall through. Accurately removes light sheet paper, film, and fines to properly prepare a container line for further processing (such as optical or robotic sorting). Minimal maintenance, no star changes required.

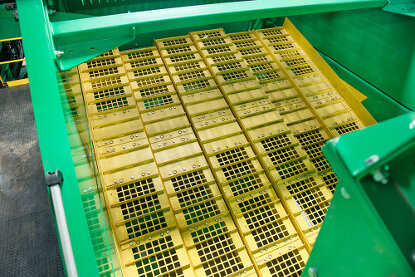

Anti-Wrapping Screen (AWS Screen)

Process at a high throughput (up to 50tph) while diverting 95% of <2” organic fines with virtually no wrapping or cleaning needs. Easily change screening size to increase flexibility. For use in mixed waste processing, C&D, MSW, and green waste.

OCC Screen

Easily adjustable star/disk spacing allows your operation to change the screening size to find the right balance of quality OCC making it over the screen and minimal amount of small browns falling through the screen with the rest of the material.