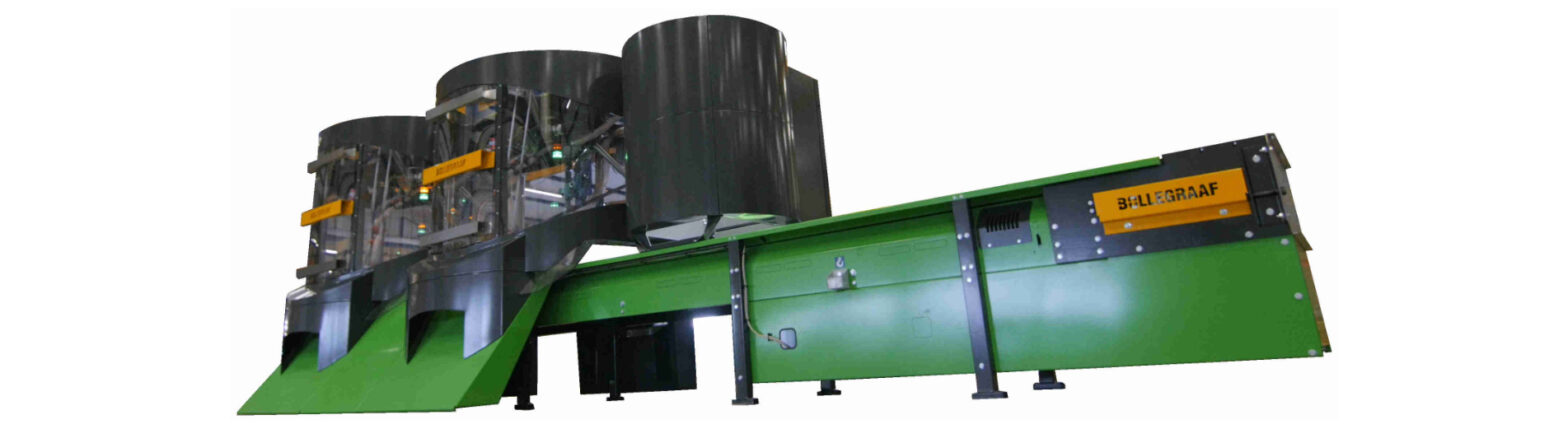

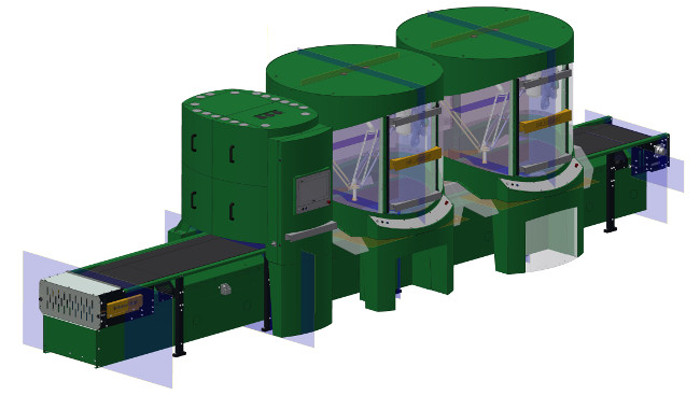

From the minds of our manufacturer, Bollegraaf, comes the fastest, most precise and most reliable robotic waste sorting solution available on the market.

RoBB-AQC is an AI-powered, fully-automated robotic sorting machine designed for improved quality control sorting in a single stream or plastics recycling system. Bollegraaf developed this new waste recycling robot model over the course of the last decade, using real in-plant testing and several iterations of the design.

See the RoBB-AQC robotic sorter performing quality control on a line of plastic bottles:

The Evolution of RoBB

What Bollegraaf learned throughout these years of experience is that a recycling robot’s arm needs to be built for recycling. It needs to be robust enough to withstand the harsh and dirty conditions of a single stream MRF. If it isn’t, it will quickly break or malfunction, and a replacement robotic sorter will only solve the problem until it suffers the same fate itself. Some arms even have parts that wear out every single day!

Bollegraaf set out to construct a robotic sorting machine that could actually withstand the harsh MRF conditions it was destined to be exposed to. They took the best parts of each past version of the robotic sorter, outfitted it with an arm that can handle the rigors of recycling, and made a unit that is easy to install with low retrofit costs.

Small footprint makes it easy to install on top of belt

The new Bollegraaf AI-powered RoBB-AQC is the first sorting robot that combines the accuracy of NIR detection with the adaptability of AI-powered learning. No other recycling robot uses near-infrared technology, which is the only technology capable of detecting items by their material composition. As a final quality control step on a container line, one RoBB robotic sorting unit will recover up to 70 picks per minute. That’s higher productivity and better reliability than two human sorters.

The robotic system is designed with flexibility in mind, as it can be placed on top of existing sort lines with very minimal retrofit costs and minimal downtime. Material selection only requires the touch of a button, and ranges from PET, HDPE, LDPE, PS and PP to Tetra Pak, OCC or paper/cardboard of various shapes and sizes.

RoBB-AQC can sort waste intermittently or continuously, regardless of working conditions on site, and requires minimal supervision and little maintenance. Its flexible, modular configuration enables you to choose the number of sorting units required and simultaneously sort up to 4 different materials per module. The robotic sorting system’s flexibility allows you to change material waste streams, so you can adapt to, for instance, changes in the stream or commodity prices.

Technical Specs

| Model | RoBB-AQC |

| Configuration | Single robot-central sort conveyor, picking to chutes on both sides of conveyor |

| Identifiable materials | Paper, cardboard, plastic & metal containers, cartons, residue |

| Sorting Speed | Up to 70 picks/min. per robot |

| Number of Sorts | Up to 4 separate sorts per robot |

| Air Consumption | <0.1 m3/min @ 7.0 BAR |

| Required Air Supply | Filtered and Dry Air, Pressure: 7.0 BAR, ISO 8573.1 Class |

| Main Circuit Breaker | 25A |

| Full Load Amperage (FLA) | 10A |

| Power consumption @ FLA | 6 kW |

| Maximum Object Weight | 4.4 lbs. (2 kg) |

| Maximum Object Size | 10″ (250 mm) |

| Sorting Conveyor Speed | 0.5 – 1.0 m/sec. |

| Suitable Operating Environment | Indoors only; 36-99°F (2-37°C) |

For more information, call us at 203-967-1100, email us at [email protected], or watch the video below!