VAN DYK Recycling Solutions and its partners are integrating AI, advanced detection systems, and presort innovations to improve purity and performance

By Recycling Product News Staff

October 20, 2025 — Recycling facilities are turning to technology to keep pace with complex materials and stricter quality demands.

Recycling facilities are adapting to rising material complexity, evolving packaging streams, and heightened quality demands. Technology is playing a growing role in addressing these pressures, and VAN DYK Recycling Solutions has been working with operators to implement equipment and system designs that respond to these changing demands.

Optical sorting: Smarter decisions with AI

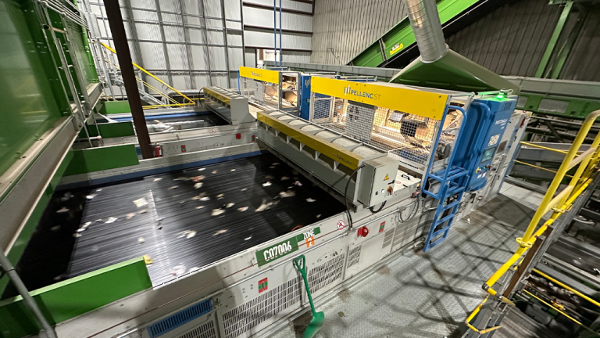

Optical sorting has long been the backbone of modern MRFs and plastics recovery facilities. VAN DYK’s optical sorting partners are building on this foundation with systems that combine AI-powered add-ons and integrate with proven NIR detection to address sorting challenges that have traditionally been difficult for the industry to resolve.

To identify and eject black plastics, TOMRA uses a laser technology called DEEP LAISER, and Pellenc ST uses Profile Detection for the same task. On the AI front, TOMRA’s GAINnext introduces a series of capabilities not available with traditional NIR to clean up paper, plastic, and used beverage cans (UBCs). Pellenc ST has a similar lineup that includes AISORT and CNS BRAIN.

These AI technologies analyze images of incoming material to intelligently detect common contamination like non-foodgrade resins, non-UBC aluminum, and white or coated cardboard, leading to higher purity levels in the fiber and container line output. Both companies continue to push development further at their respective material and technology test centers, where AI models are trained on real-world materials to refine accuracy over time.

Enhanced performance with system add-ons

VAN DYK works with operators to enhance the performance of optical sorters through equipment add-ons designed to improve consistency and accuracy. Disc spreaders ensure material is evenly distributed across the belt for maximum visibility and enhanced sorting performance. Optical acceleration belts can be outfitted with air assist technology to prevent light materials from floating around, improving ejection accuracy and reducing missorts. These enhancements translate directly into cleaner commodities and stronger plant economics.

Data intelligence in real time

VAN DYK’s exclusive partnership with Greyparrot brings a high-resolution, AI-powered analytics platform to MRFs. By providing minute-to-minute insights into inbound and outbound material streams, Greyparrot analyzers monitor sorting performance on each commodity. Greyparrot flags inefficiencies instantly so operators can take action before valuable materials — and profits — are lost. Greyparrot’s AI has been trained to identify 111 waste categories and is continually learning more. This technology is poised to transform how facilities track, analyze, and optimize performance in real time.

Rethinking the presort with splitter technology

Upstream, the Günther SPLITTER is a non-wrapping, maintenance-free spiral shaft screen for front-end sizing in a MRF. Ideal for size separation in this setting, the SPLITTER is customizable and can be built with six different axle distances and 11 different auger sizes. This means the SPLITTER screen can be built 33 different ways to properly size and separate materials. Its original shaft technology screens out hazards, boosts safety, and eliminates the need for manual sorters in hazardous areas of the plant. By removing problematic items early, downstream equipment performs more efficiently and sustains less wear.

This article originally appeared in the 2025 Technology Special Issue of Recycling Product News.