New installations, deals and partnerships mark strong year for Van Dyk Recycling Solutions

NOVA Circular Solutions to Open Film Recycling Plant

Freepoint Eco-Systems LLC Begins Chemical Recycling of Plastics

Waste Connections Opens Facility with Advanced Fire Prevention

Atlantic Coast Recycling Opens Redeveloped MRF

FCC Environmental Services Opens C&D System

Mazza Recycling Services to Build New C&D Facility

Ontario Selects Processors for EPR Rollout

Ontario Selects Processors for EPR Rollout

GFL to Open Edmonton Single Stream MRF

Greyparrot Analyzer – Try Before You Buy!

Murphy Road Recycling LLC Invests in AI Software

Murphy Road Recycling LLC Upgrades Fiber Line

Balcones Sees Measurable Improvement with Optical Upgrade

USA Pellenc ST sells 300th Machine in USA

Sunnyvale, CA Improves Organics System with Smicon Equipment

Bollegraaf – Built to Last

Bollegraaf – Built to Last

Republic Services Upgrades Las Vegas Site Baler

Van Dyk Hires Plastics Expert to Expand Offerings

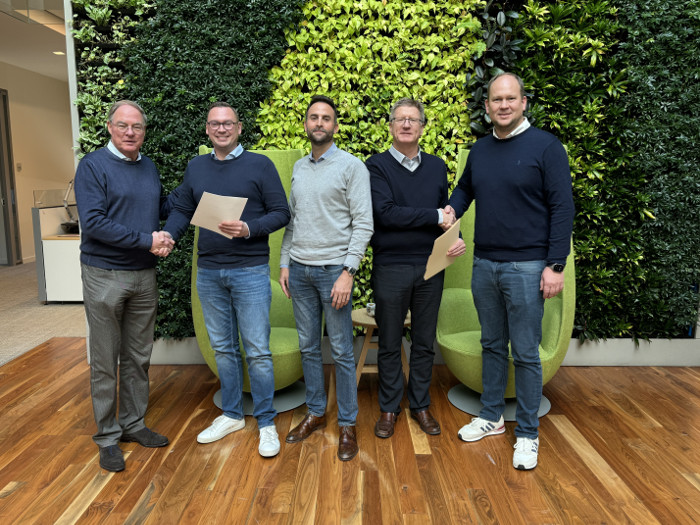

Van Dyk Partners with Battery Recycler